Category: Material Handling

Southeast Industrial Equipment is the largest material handling dealership in the Southeast. SIE is a Toyota forklift dealership dedicated to all lines of equipment we offer. With locations in Charlotte, Duncan, Florence, Charleston, Columbia, Wilson, Savannah, Richmond, and Raleigh we offer superior servicing capabilities throughout the Southeast. The material handling equipment we carry ranges from Capacity yard spotters, Cushman utility vehicles, Landoll very narrow aisle forklifts, to Kalmar large pneumatics.

SIE Wins The Prestigious TMHU President’s Award For The Fourth Consecutive Year!

During the Toyota Materials Handling, U.S.A. (TMHU) Annual Dealer Meeting Toyota recognizes the top dealerships in the North American Market with elite awards for their accomplishments from the year before.

During the Toyota Materials Handling, U.S.A. (TMHU) Annual Dealer Meeting Toyota recognizes the top dealerships in the North American Market with elite awards for their accomplishments from the year before.

In order to obtain Service Excellence a dealership must excel in PM completion, Toyota Service Market Share, Customer Satisfaction, and Training. SIE was recognized for Service Excellence in 2018.

For Parts Excellence a dealership must excel in Parts Inventory Management, Parts Sales, Training, Parts Market Share, and Customer Satisfaction. SIE was recognized for Parts Excellence in 2018.

Sales Excellence is obtained by a dealership for excelling in the areas of Sales Market Share, Sales Coverage, Training, and customer satisfaction. Sales Elite is given to the top dealers in Volume of Toyota forklift. SIE was recognized as a Sales Elite recipient in 2018.

Finally, Toyota’s President’s Award is only given to the dealerships that excel in ALL areas of the business and meet the top % of their markets. SIE was recognized as a President’s Award winner for 2018!

The news was announced by Southeast Industrial Equipment President, Cory Thorne. – “I want to thank each and every one of you for your contributions in helping SIE earn these awards. We have now been recognized with Toyota’s prestigious President’s Award for the 4th straight year, and I can’t say THANK YOU enough!”

SIE Donates Forklifts & Pallet Jacks to Support Red Cross Hurricane Florence Relief

October 12th, 2018 — In collaboration with Toyota Materials Handling U.S.A. (TMHU), Southeast Industrial Equipment’s rental and parts departments responded to numerous American Red Cross requests for materials handling equipment rentals to assist in Hurricane Florence relief efforts at warehouse locations near SIE’s Florence, SC, Columbia, SC, Wilson, NC, and Hampton Roads, VA branches.

Hurricane Florence has had devastating impacts in North and South Carolina. After making landfall in the Southeast, many rivers swollen with rain, have caused historic flooding and threatened homes, industries, and infrastructure. Preliminary information suggests that between 8,000 to 10,000 homes may have suffered major damage or were destroyed. More than 3,500 Red Cross disaster workers from all over the country are helping to shelter, feed and support people affected. Working with partners, the Red Cross has served more than 921,600 meals and snacks, provided more than 114,700 overnight stays (92% by the Red Cross), distributed more than 138,200 relief items like diapers and comfort kits for people forced from their homes.

The Red Cross submitted forklift rental requests to TMHU who then got in touch with executives at Southeast Industrial Equipment to respond with immediate assistance. SIE delivered 11 Toyota hand pallet jacks and 13 Toyota forklifts to Red Cross locations throughout the devastation to assist in warehouse facilities to move pallets of water, food, and other items needed. Southeast Industrial Equipment donated one month of the rental equipment to the Red Cross and TMHU will donate the remaining months expenses.

Nationally, Toyota Material Handling assists the Red Cross with volunteer forklift training and encourages employees to become certified Red Cross forklift operators. The national partnership with the American Red Cross is Toyota’s commitment to support local communities and neighbors to ensure everyone gets through tough times together.

It is a privilege of SIE to be able to partner with Toyota Materials Handling, U.S.A. to help those in need during hard times.

Forklift Tires: What You Need To Know And When They Should Be Replaced

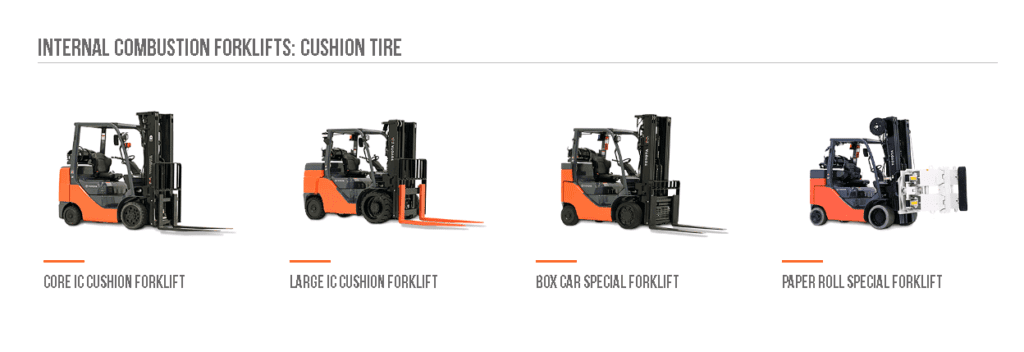

Are you like most, wondering what type of tires you need for your forklift? What if you don’t know when to replace your forklift tires? These are critical factors that could save you and your company a great deal of time and money. In this blog we will cover the two main types of forklift tires and the wear and tear to look for.

Forklift tires come in three different varieties cushion, solid pneumatic and air-filled pneumatic. Cushion forklift tires are primarily used indoors or on smooth outdoor surfaces. These tires can puncture easily, therefore, they are not suited for rough terrain. Pneumatic forklift tires are similar to a car or truck tire when air-filled for more comfort. Solid pneumatic forklift tires are used in outdoor applications where debris can easily make your tire go flat. Both cushion and pneumatic tires are offered in treaded or smooth options, however, you need to be aware of the moisture around the operation in order to make an educated decision on what type of tire you will need for traction.

Worn forklift tires can cause more damage to your lift truck that you would think. The axle of your forklift is typically specific to what type of tire it should have. Forklifts do not have suspension systems so the tires absorb the weight of the truck and the load. Therefore, the more worn your tires are the more pressure is put on the axle of the forklift. In order to reduce the risk of axle and other damage to your lift trucks, tires must be part of the daily operator checklist for each unit before using them. “Did you know: after a tire has worn 40%, the forklift and the driver will absorb over 84% of the shock if it’s being run over a rough surface. The transmission has to work much harder to turn the tires the same amount of rotation, which can result in a breakdown.” – tmhnc.com/blog If an operator starts to see chunking, cracking, tearing and/or flat spots it is time to replace your forklift tires. Below is an example of tires that have worn down to the “safety line” that some forklift tires come with and an example of tire chunking.

Replacing forklift tires can be very dangerous and should not be performed but anyone not properly trained to do so. If you are in need of tire replacement services, contact Southeast Industrial Equipment at any one of our 10 branch locations throughout South Carolina, North Carolina, Georgia or Virginia. See our forklift tire guide below for more details.

SIE Supports the 5th Annual National Forklift Safety Day June 12th 2018

“Safety is the cornerstone of our industry, and operator training is a major component in reducing worker injuries and fatalities,” said Brett Wood, president and CEO of Toyota Material Handling North America and chairman of ITA (see full article.)

June 12, 2018 is the fifth annual National Forklift Safety Day. Created by the Industrial Truck Association (ITA), National Forklift Safety Day is an annual event for the forklift industry to emphasize the importance of operator training and the safe use of forklifts.

Southeast Industrial Equipment’s main focus is to ensure that we provide our customers with the top of the line and safest material handling equipment in the industry. It is imperative that all operators are properly trained to operate the lift trucks they handle costly materials with day in and day out. SIE offers in-house operator safety and certification training at our Charlotte, North Carolina and Duncan, South Carolina forklift dealership locations on a monthly basis. We also offer the convenience of training your operators on-site at your location and numerous train the trainer programs where you become the trainer to save time, damages, accidents, money and more.

TMHU President Jeff Rufener said, “Toyota’s number one priority is to create safe products, so we’re naturally big supporters of National Forklift Safety Day. Implementing safety audits and training in your organization can reduce injuries, while preventing loss of resources and lowering maintenance costs.” (Modern Materials Handling article on National Forklift Safety Day)

For more on forklift safety in the workplace, check out the resources below.

https://www.toyotaforklift.com/blog/know-your-forklift-trip-points

https://www.osha.gov/dte/library/pit/daily_pit_checklist.html

https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9828

The Solution to Changing Boat Storage Trends with Toyota’s Marina Forklift

Toyota’s High Capacity Marina Forklift is the solution to changing boat storage trends and the unique challenges faced by marina owners and dock workers.

Once considered too costly for many boat owners, the advantages of dry storage (protection from the elements and advancements in building materials technology that make warehouses better able to withstand hurricanes, as well as increasing the load-bearing capabilities of the racking) have created an increased demand in many marinas. This also creates industry-specific challenges for marina and dock owners, such how to quickly access and move boats from the warehouse to the water, and how to house all those boats that were once in slip storage.

Marina owners are looking for specialty equipment that can maximize efficiency while maintaining safety and protecting their customers’ investments. The Toyota High Capacity Marina Forklift is the answer to those challenges. Customized for your application, with a lifting capacity of 15,000 – 55,000lbs, and forks that can handle any boat size you need to accommodate, this forklift can get the job done.

State of the art technology gives operators eyes in the back of their heads with must-have tools like an on-board rack height calculator and a backup camera, all in real-time and displayed on a 7” MD4 screen.

A two-stage mast built to reach new heights, gives you the ability to stack beyond traditional two and three-tiered racks, allowing marina owners to build up instead of out, and maximizing space. A forklift with negative lift, standard on Toyota’s High Capacity Marina Forklift, eliminates the need for cranes when lowering boats into the water, and optional wireless remote control gives operators the ultimate advantage in precision maneuverability.

Adapting to changing conditions and responding to new trends are critical to creating success in any industry. Having the right equipment, at the right time, along with a great support network can make all the difference. Contact your local Southeast Industrial Equipment branch today to see if the Toyota High Capacity Marina Forklift is right for your application.

SIE Wins Toyota President’s Award for the 3rd Consecutive Year

Toyota Materials Handling, U.S.A. announced the recipient’s of the prestigious President’s Award for outstanding performance in 2017 at the 2018 Dealer Meeting held in Tucson, Arizona. Southeast Industrial Equipment was one of 15 dealers nationwide to win the elite award for the third consecutive year! Only dealers who perform at the highest level in parts, service and equipment sales, customer satisfaction and overall operations win this accolade which was featured in a Material Handling Network article in April, 2018! “The dedication to go above and beyond for our customers is what sets the President’s Award winners apart,” said Jeff Rufener, president of TMHU. “They are driven to deliver the best customer experience in the industry and the President’s Award is our way of honoring them for their unwavering commitment.” – TOYOTA’S ANNUAL PRESIDENT’S AWARD HONORS TOP FORKLIFT DEALERS Monday, April 9, 2018

Southeast Industrial Equipment also received the Sales Elite, Parts Excellence and Service Excellence awards during this meeting. Working together throughout 10 branch locations in the Southeast to serve our customers with the best customer service and high quality materials handling equipment has earned Southeast Industrial Equipment these awards consecutively.

In addition, SIE has won the 2018 Toyota Commercial Finance Ambassador Award in recognition of continued support and achieving $150,000,000 in lease and retail outstanding with TCF.

Check out Toyota Material Handling, U.S.A. commitment to excellence in 2018 with this video below.

6 Questions to Ask When Choosing The Right Forklift Attachments For Your Lifts

Forklift attachments are highly underrated; many people think that attachments are only useful for certain industries handling unique loads, but that is not the case. In fact, forklift attachments can add ease to handling any load.

Utilizing the right attachment can reduce handling time, manpower, fuel consumption, and the chance of damaging the product. There are several types of forklift attachments, so how do you know which is the right one for you? When choosing an attachment for your forklift, here are 6 questions to ask:

- What is the weight of the load?

- What height does the load need to be lifted?

- How do you want to handle the load?

- How many hydraulic functions will be required?

- Will the attachment be required full time or part time?

- Will operators need training in order to operate the attachment? If so, how many operators will need training?

At Southeast Industrial Equipment we have a full staff of educated territory managers and support managers that can assist you with answering these questions, as well as, walk you through the most popular forklift attachments as seen in the infographic below. From paper roll handlers to bale clamps, the possibilities for forklift attachments are virtually endless.

Considering the purchase of an attachment? Contact one of our experienced territory managers to find out if purchasing an attachment makes sense for your application.

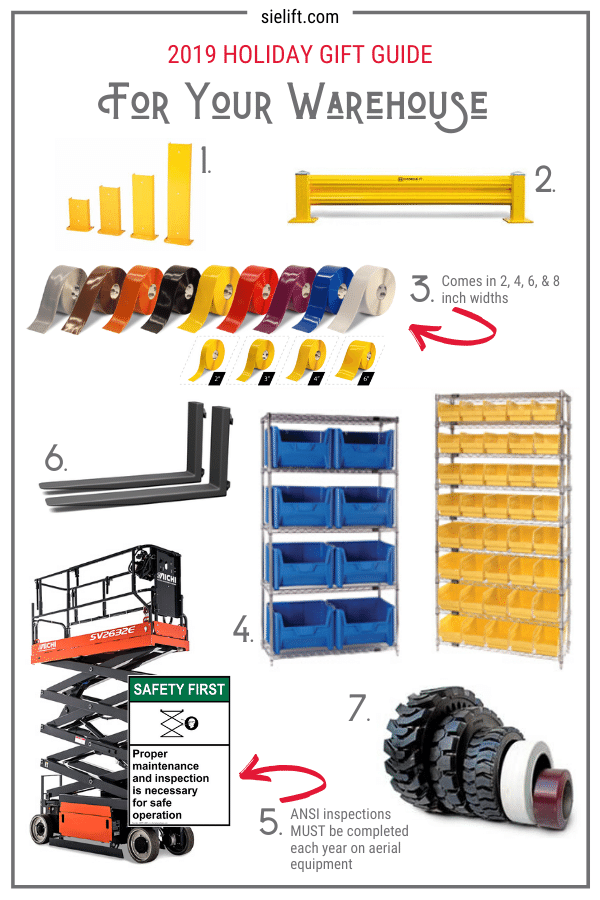

Online Warehouse Catalog Makes Shopping Easy

Material handling and safety equipment at your fingertips with our online warehouse catalog.

Online shopping is the easiest way to shop these days and why shouldn’t it be the same for material handling and safety equipment? Southeast Industrial Equipment has extended this luxury to our customers with our easy-to-use online catalog. Where you will find quality material handling and industrial supplies for all your needs.

To get started either click one of the product pictures, select a category from the Shop our Catalog drop down menu, or type a keyword in the POWER SEARCH box and click on the GO button. You will find thousands of the industry’s best products and values!

Key features for easy shopping:

- Several search options making it easy for you to find what you need.

- Search by manufacturer

- Search by keyword

- Search by catalog part number

- Safe Shopping Experience

- Order Status Checking

- Quick Order Options

- Find everything from Racking Systems, Mezzanines, Safety Equipment, Storage Solutions and so much more!

No matter what you need, Southeast Industrial Equipment has made it easy for you to get everything from racking to safety products using our online warehouse catalog. Request a FREE SITE SURVEY today to see how we can help you utilize every square foot our your application with our customized engineered solutions!

No matter what you need, Southeast Industrial Equipment has made it easy for you to get everything from racking to safety products using our online warehouse catalog. Request a FREE SITE SURVEY today to see how we can help you utilize every square foot our your application with our customized engineered solutions!

Don’t Make A Costly Decision

Your company needs a new forklift, but where do you begin? Whether you’re a seasoned vet or a beginner, choosing a new piece of equipment can be stressful.

The pressure is on to find the perfect forklift that will increase productivity without breaking the bank. There are several factors that go into choosing the right piece of equipment; here’s what you need to know to make your mission a success.

Indoors vs. Outdoors

The environment you operate in answers the first major question, Electric or Internal Combustion (IC).

If you will be operating inside, electric is the way to go. Electric forklifts offer decreased fumes and noise, making them ideal for an indoor warehouse environment.

While Electric forklifts might cost more initially, they tend to have a lower operating cost per year than Internal Combustion (IC) Lifts. Electric forklifts don’t require fuel or oil changes but they aren’t totally maintenance free, requiring upkeep for batteries. If the water level inside the battery gets too low it can dry out, requiring a replacement or repair. You must also factor in the cost of a charging station and consider purchasing a backup battery.

If you need a forklift that can handle rough terrain and the wear and tear of being outdoors, then you’ll want an Internal Combustion Lift. Designed to handle larger loads than their electric counterparts, IC lifts can run on Diesel, Liquid Petroleum Gas (LPG), or Gasoline. Diesel engines are designed for uneven surfaces and heavy loads and work well with attachments. LPG lift trucks are great if you need a versatile piece of equipment that can operate indoors and outdoors.

Selecting a model

Now that you’ve decided between Electric and IC, it’s time to get specific. Knowing your lifting capacity and height needs will guide you to the right model. Many buyers find it useful to purchase a lift that slightly exceeds their current requirements.

Overall Cost of Equipment

Once you’ve found the perfect model, it’s easy to get caught up in the initial cost and lowest price tag, but doing so can cost you more. When in the market for new equipment it’s important to think long-term and consider the lifetime cost of your forklift. Used equipment can be a bargain, but new equipment offers warranties and peace of mind that some used equipment may not afford.

Knowing what the dealer has to offer helps you tremendously. Ask about services and maintenance plans that support your new investment. Find out if your dealer provides OEM parts you may need, and ask about any warranty the lift may come with.

Most importantly, do your research before hitting the market. Take your time and don’t just jump at the cheapest option.