Category: Warehouse Products

Southeast Industrial Equipment is the full solution to all of your materials handling needs including all of your warehouse products. We offer a wide variety of warehouse products from racking solutions to the design your entire facility to increase productivity and keep your downtime at bay. Read our blog about the different types of racking that may fit your application. Browse our warehouse catalog where we offer safety equipment, dock solution, cabinets, containers, and more.

You Can Never Be Too Safe – The Benefits of Safety Equipment.

When it comes to your business, safety should always be the number one priority. Safety is the key to creating and maintaining a productive and profitable working environment.

Under what’s known as the General Duty Clause of the Occupational Safety and Health Act (OSHA) employers are responsible for maintaining a work environment free from conditions that might cause death or injury. Employers whose workplace present dangerous conditions risk violating the General Duty Clause unless they take measures to lessen the danger. If that’s not scary enough, the National Institute for Occupational Safety and Health (NIOSH) reported there are 19,000 forklift/pedestrian incidents each year. On average, those incidents cost employers $38,000 in direct expenses and almost four times as much for indirect costs.

Southeast Industrial Equipment offers an affordable safety package complete with fire extinguishers, back-up alarms, and strobe lights. Together, these inexpensive additions are a great way to help reduce the chances of forklift accidents.

Fire Extinguishers

While OSHA does not require forklifts to be equipped with fire extinguishers, quick access to one can be the difference between life and death! Fire extinguishers are an especially wise option on LP-Gas forklifts operated in areas containing flammable liquids.

Back-up Alarms and Strobe Lights

Workers die every year from being backed over by vehicles. From 2005 -2010, forklifts ranked fourth in the number of these fatalities. Back-up alarms are one of the most valuable tools for preventing forklift injuries and fatalities. While some back-up alarms automatically adjust their volume to be greater than the ambient noise of the facility, workers can become immune to repetitive sounds. Some PPE dampens noise, further limiting the effectiveness of the alarm. This means back-up alarms are best used in conjunction with visual alarms, like strobe lights or blue lights.

Strobe lights on forklifts let everyone in the vicinity know that a truck is present. The flashing lights provide a visual warning system alerting employees of the whereabouts of the truck. In work environments where noise levels are elevated and back-up alarms might go unnoticed, lights provide an additional layer of protection to employees.

Blue Safety Lights

If you’re truly committed to safety, consider upgrading to the blue safety light. The blue light shines on the floor in front of or behind the truck, telling pedestrians not just where the truck is, but where it’s going. Most importantly, the blue light can be seen around corners and blind spots, drastically reducing potential for collisions.

“It is better to be safe than sorry.” It’s cliché because it’s true. When it comes to protecting your business and employees, you can never be too safe. Contact SIE today to discuss how we can help you protect your employees and your business.

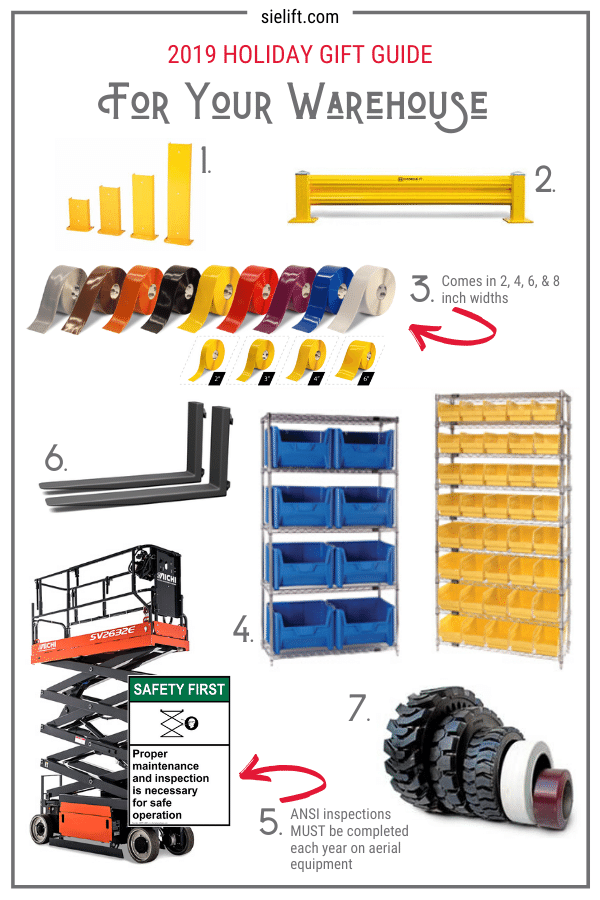

5 TOP Pieces of Warehouse Equipment You Won’t Want to Work Without!

With all of today’s modern technological advances we are spoiled with the convenience of automated tools to do it all. The materials handling industry is following suit with the every-growing and “need it now” way of business. Our customers choose us for quality equipment, rentals, service, & parts but what many do not know is that we offer a HUGE selection of warehouse equipment & products to outfit your entire operation.

In studying the buying habits of the businesses we serve over the past year, we have compiled the top 5 pieces of warehouse equipment that are flying off the “racking”. Take for example, the popular stretch wrap machine that makes wrapping pallets a breeze. Or the multiple options of heavy duty floor tape line we carry, the easiest way to set up boundaries and safety zones. So in no particular order, let’s dive in!

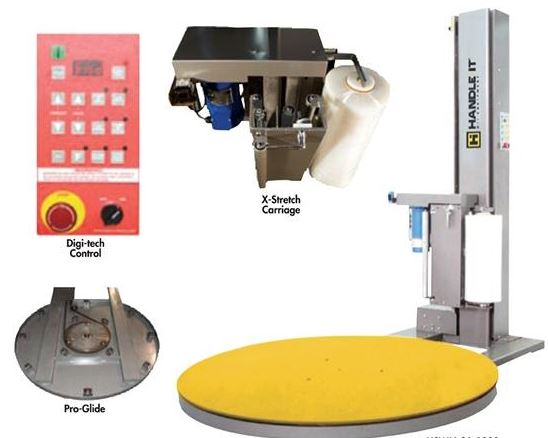

1 – The X-Stretch Semi – Automatic Stretch Wrap Machine 250% pre-stretch film carriage provides superior film economy, film tension, and user safety. The robust PRO-GLIDE turntable support system is maintenance free and the DIGI-TECH control unit features unique functions to wrap any pallet type. Expertly engineered for demanding applications. This unit is designed to wrap 35-40 loads per day with the capability of wrapping up to 20 loads per hour. Units ship fully assembled and ready to use!

Features

- Photo eye height sensor

- 3000 lb capacity

- Manual film tensioner

- Fully adjustable wrap cycles

Available Options • Standard loading ramp for easy pallet jack use • Extended length heavy duty loading ramp for electric equipment • Scale package with digital weight indicator SWM-SA-0500 ®

2 – The Electric Powered Floor/Shop Cranes (power hoist & power in/out boom) are popular for moving loads quickly, easily, and safely. 24V DC drive and lift motor handles heavy-duty jobs and the ergonomic handle features easy-to-operate throttle with infinite adjustment of forward and reverse speeds, lift/lower controls, proprietary safety-enhancing emergency reverse function, and horn. Includes an electromagnetic disc brake with automatic dead-man feature that activates when user releases the handle.

Features

- Poly-on-steel steer and load wheels.

- 3-4 hour operation at full charge – 8 hours when used intermittently.

- Includes rigid hook with safety latch.

3 – Reduce risks to workers with the ergonomic and safety conscious Clamp & Go Dolly Handle. Attach Clamp+GOTM to the sidewall of your drum dolly with a downward push to engage the quick-coupling mechanism. Now you’ve got a drum dolly with a handle to pull or push to move your drum around. Easily move into and out of confined areas.

Features

- Clamps onto dolly for safer, ergonomic drum transport

- Adjusts for various dolly wall heights

- Pivoting handle that stores upright when not in use

- Designed for use with a drum weighing up to 1000 Lb.

4 – The multi-functional Drum Lifter / Rotator / Transporter has a hand pump that lifts drums from ground level to a raised height of 62″ to bottom of drum in vertical position. For use with 55-gallon steel or fiber drums. A hand gear mechanism provides the controlled 360° rotation of the drum. A floor lock is standard to stabilize the unit in a fixed position.

Features

- The safest and most convenient way to handle open or closed end drums.

- 550 lb. capacity.

5 – The Pallet Leveler progressively lowers as pallet is loaded and raises as pallet is unloaded. Three heavy duty calibrated springs used in combination according to desired load range. Bearing supported carousel for easy turning. Built-in 5-3/4 x 39″ fork pockets for ease of transport.

Features

- Reduce injury from bending and lifting.

- 400 – 4,500 Capacity

- 72 x 50 x 50″ Load size

Contact SIE today for you FREE copy of our material handling and safety products catalog today or click here Warehouse Supplies Catalog to request your FREE QUOTE now!

Check out all of these product videos here and more!

Check out all of these product videos here and more!

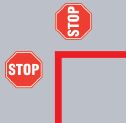

Floor Tape Tips to a Safer Warehouse

First things first, in order to safely guide daily operations of your facility, we suggest segmenting departments into designated areas with the highest quality floor tape for safety and simple organization. After all, the key to a safe and productive facility or warehouse is in the planning. “The more clarity, logic and clear communication you can bring to a workplace environment, the

more safely and efficiently it will operate.” – Mighty Line Floor Marking Guide

When choosing the type of floor tape to the safety signs you will need for your warehouse consider the 4 D’s.

When choosing the type of floor tape to the safety signs you will need for your warehouse consider the 4 D’s.

- Draft daily productivity routes – Consider the basics by utilizing an engineering partner to layout the basics of your operation to find the best possible outcome for daily routines. I.E. Shipping , Receiving, Machining, and Inspection areas. Use multiple colors of floor tape to define each area.

- Designate operational areas – Depending on the width of the aisles between your racking systems, a safe distance to stay away from the upright beams needs to be clearly marked for pedestrians, operators, and equipment.

- Define potential hazard locations – Does your warehouse have bays where safety apparel is needed due to the equipment in use? Do you work with hazardous materials? Do you need to mark off container storage that should not be handled? The use of floor tape and safety signs to clearly mark dangerous locations is imperative for safe a operation.

- Determine likely collision points – Lift trucks, forklifts, floor cleaning equipment, guided vehicles, and other equipment are an integral part of the productivity of your facility. They can also be the most dangerous ticket items for collisions with other equipment, racking systems, products, and even operators and pedestrians. Clearly labeling tight and accident prone areas can significantly reduce the risk of these incidents occurring.

Differentiating the types and color of the floor tape you choose to mark specific areas are as follows:

YELLOW: Use to signify safe paths for walking

RED: For dangerous areas, emergency exit areas

WHITE: Production equipment: machines, carts, incoming racks

GREEN: Safety-related areas: eye wash stations, safety showers, etc

ORANGE: Machinery parts areas

BLUE: Works in progress/equipment under repair zones

BLACK: Finished goods area

YELLOW WITH BLACK DIAGONALS: Extra caution walkways

WHITE WITH RED DIAGONALS: Safety equipment areas: Fire extinguishers, electrical panels, AED machines, & more

Watch how easy it is to install >>

Southeast Industrial Equipment team consists of highly trained and experienced professionals and partners with the equipment and knowledge to assist you in every step of the warehouse/facility planning process. Contact us today for a FREE site evaluation (866) 696-9125.

DOWNLOAD the full Mighty Line Floor Marking Guide here > Floor Marking Guide

Guide To Proven Warehouse Solutions

Read the guide to “proven” warehouse solutions designed to work for your application by Toyota Industrial Equipment. A highly productive warehouse design is paramount to productivity. In order to optimize your warehouse functionality it is imperative that you source the right materials handling equipment, service solution, replacement parts, and a primary point of contact.

How To Be Selective With Your Selective Racking Systems

There is a wide variety of racking systems on the market today, so how do you know what is right for your application?

Here at Southeast Industrial Equipment we excel at providing our customers with a customized solution for your material handling needs. This means not only offering the world’s number one lift truck but providing the latest in engineered solutions and warehouse products for our customers. Building space, equipment and loads must be determined and kept in mind when selecting the correct system that works for you.

Contact us to help you with your pallet density and space utilization needs today!

BROWSE OUR CATALOG

- START WITH THE BASICS! Along with the standard length, width and height, knowing the type of pallet and loaded pallet weight will determine capacity needed for your beams and uprights. Educating yourself and your SIE Territory Manager on storage requirements and warehouse needs will increase facility safety and productivity.

- KNOW YOUR SKU COUNT! Are you aware of what your warehouse SKU count is and how quickly the items on your shelves need to be accessed? Being able to answer critical questions such as those is paramount to finding the system that works best for your facility. Facilities with larger SKU counts or store time sensitive products are great candidates for Selective Racking because they’re capable of 100% selectivity for their products.

- DETERMINE LOADING CONDITIONS! Does your facility load with the UDL (Uniformly Distributed Load) method or Point Loads? Knowing your loading conditions will aid your search for the correct beams, which will tell you the capacity of your warehouse, as well as, the number of pallet positions you’ll be able to hold.

- VARIETY IS KEY! Southeast Industrial Equipment offers a wide variety of both static and dynamic racking solutions that are sure to keep your facility running to its full capacity. The choice between Selective, Push Back, Pallet Flow, and Drive-In racking options can be a daunting task, let an SIE Territory Manager help you decide which type is best for your warehouse.

- CHOOSE SOUTHEAST INDUSTRIAL EQUIPMENT! The team at Southeast Industrial Equipment will provide you with a hands on approach to making your warehouse work hard for you. We will help you fit your facility with the best racking solution for your products to decrease product damage and increase productivity and efficiency.

Contact one of our local territory managers and territory support managers today to address any questions or concerns with your current racking systems or to schedule a site survey to work with SIE in your next facility build.