If you’re in the material handling industry chances are you need a fleet of lift trucks. Deciding whether to use electric or fuel powered trucks can be difficult. The forklift’s application will determine what type you need for your business.

Electric forklifts have no harmful emissions, and are extremely quiet in use. The battery acts as a counterbalance, this combined with the counterweight makes them highly maneuverable, stable and compact in size. The center of gravity is very low providing stability even at greater lift heights. Electric forklifts have only an accelerator and brake pedal, no clutch or inching pedal, making them less complicated to drive. Though the initial cost may be higher than fuel powered forklifts, their maintenance and servicing cost are considerably less over the lifetime of the truck. They are mechanically simple having no transmission or torque converter. With Electric trucks you will need a charging station and it takes about eight hours to fully charge a battery. Their ideal use is inside away from moisture, and they are great in tighter spaces.

If your application is outside, on a rough terrain, and you need a large lifting capacity, diesel is the way to go. Diesel forklifts are also great if you require attachments, because have the extra power needed. These trucks are available anytime day or night, with no charging or battery charging station required. These trucks generally hold their value, and have a higher residual. The engine componentry is very sturdy and operates at low “revs” so the trucks have a long life span. Diesel trucks also have a fuel gage to let you know when it’s time to refill. These trucks are the goliath of lift trucks with capacities over 50,000lbs.

Liquefied petroleum gas (LPG) forklifts have always been popular with their competitive pricing and diverse indoor/outdoor usage. They are convenient and work around the clock. Parts are readily available due to the engines being derived from car engines. They are at the top list when it comes to travel speeds, rates of acceleration, and lift speeds, making them highly sought after. LPG powered forklifts also do not require charging or a charging station. Their versatility is great when you need a truck to perform inside and outside. Though it is an internal combustion engine they are still very quiet with low vibrations for driver comfort.

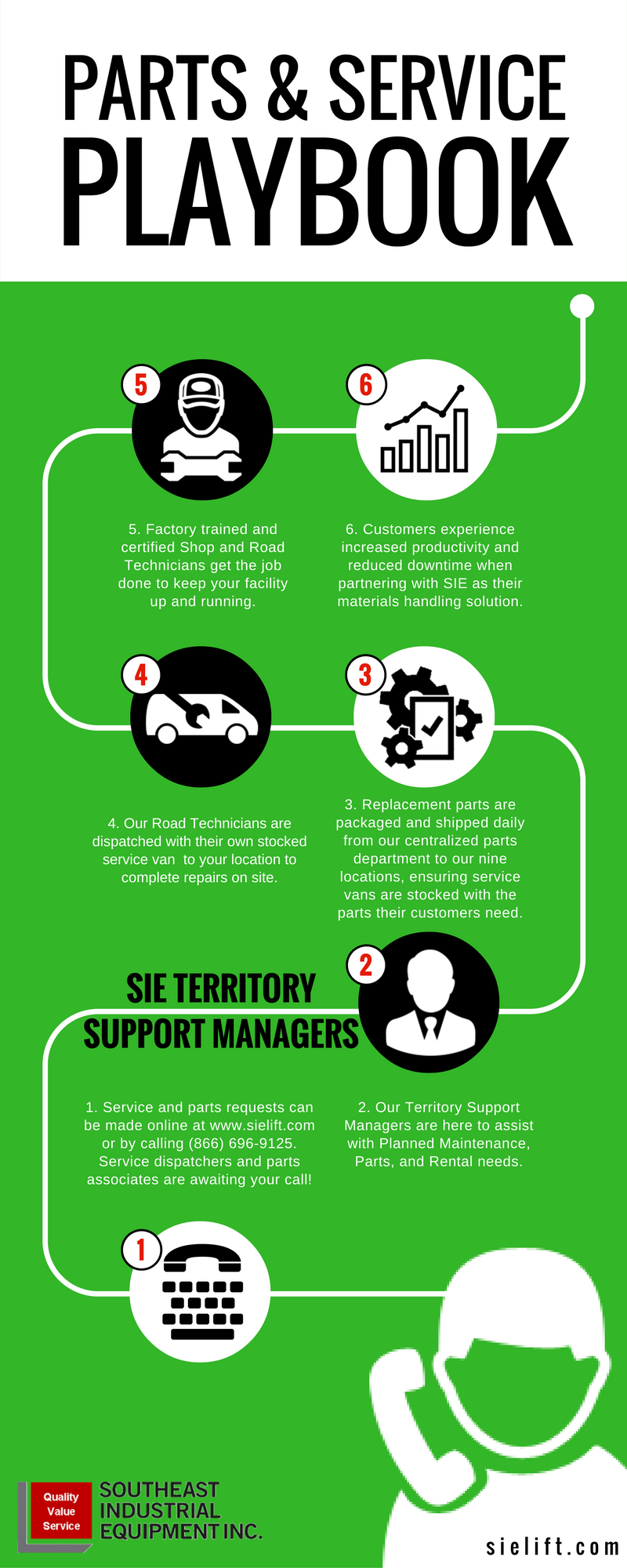

Let us come out to view your application and help you decide what the best lift truck is for your needs. We sell new and used lift trucks; view our inventory at www.sielift.com or call us (866)-696-9125.

https://www.bendigomitchell.com/kb/forklift-power

Bendi – The leader in articulated forklifts

Bendi – The leader in articulated forklifts Drexel – The very narrow aisle and narrow aisle long load side loading solution.

Drexel – The very narrow aisle and narrow aisle long load side loading solution.