The 3-Wheel electric forklift from Toyota is an innovative and durable piece of equipment that will help your business flourish. With industry best lead times for this vehicle, you could get your own in only 10 weeks! This forklift has many unique strengths and components that make it special, and it will be a great addition to any indoor operation. The most notable feature of this lift is the 3 wheeled design that it’s named after. Unlike a traditional 4- wheeled forklift, the 3-wheel forklift has two wheels in the front of the lift and only one rear wheel. This 3-wheel design allows for greater stability as well as easier navigation through narrow spaces.

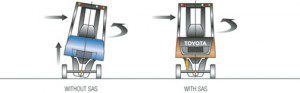

A traditional forklift with 4 wheels can be prone to tipovers and other accidents. If they are loaded with too heavy of a load or are traveling at high speeds the forklift will be at risk of a dangerous tipover. OSHA reports that 24% of all forklift fatalities are caused by tipovers. This goes to show how serious of an issue tipovers can be. A 3-wheel forklift offers greater stability due to the triangular weight distribution its design offers. The single back wheel brings more weight to a central distribution making it more difficult for the vehicle to tip over. This is why 3-wheel lifts are not equipped with Toyota’s System of Active Stability, as the vehicle is already extremely stable on its own.

The single rear wheel also allows for a much smaller turn radius than a traditional forklift. This makes it possible for these vehicles to operate in aisles that would be too narrow for a 4-wheeled lift. It is able to operate comfortably in aisles that are ten foot wide, while a similar sized 4-wheeled electric lift would need a foot or more of extra space to properly operate. This allows for business owners to add more racks to their warehouse and better utilize their facility’s space.

If you place an order for a 3-wheel electric forklift you will have it in only 10 weeks. So call us today at (704) 399-9700 to speak to one of our equipment experts. To view our other forklift options, click here.

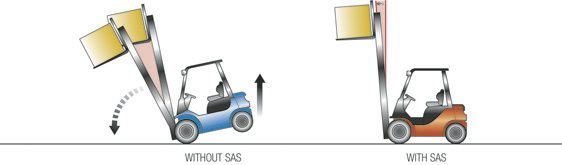

One of the most common problems warehouse owners face is a lack of storage space. Without extensive changes to a building, there is no way to expand the horizontal area in your warehouse. An easy solution to this problem is to think vertically rather than horizontally. The vertical space within warehouses is something that has been overlooked in the past, but in recent years has become more widely used. This is thanks in part to new technology in equipment and racking solutions.

One of the most common problems warehouse owners face is a lack of storage space. Without extensive changes to a building, there is no way to expand the horizontal area in your warehouse. An easy solution to this problem is to think vertically rather than horizontally. The vertical space within warehouses is something that has been overlooked in the past, but in recent years has become more widely used. This is thanks in part to new technology in equipment and racking solutions.