The threat of a tipover is a frightening thought for anyone operating a forklift. OSHA reports that 42% of all forklift fatalities are caused by tipovers. The areas in which forklifts are operated are oftentimes unpredictable and can force operators into difficult situations. Fortunately, the incredible engineers at Toyota developed a solution to help mitigate these problems and protect forklift drivers.

In 1999 Toyota introduced the System of Active Stability (SAS) and all 4-wheel Toyota forklifts have been equipped with SAS to this day. SAS is able to take over 3,000 readings per second to detect any unsafe operating conditions. If unsafe conditions are detected, the system then activates one of its two main features to improve the stability of the forklift.

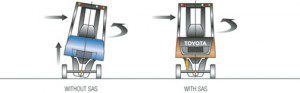

The first of these features is the Active Control Rear Stabilizer System. This feature is able to quickly lock the rear axle of the forklift and in turn convert the lift’s triangular stability pattern into a rectangular pattern. This change reduces the risk of a lateral tipover and keeps the forklift as stable as possible.

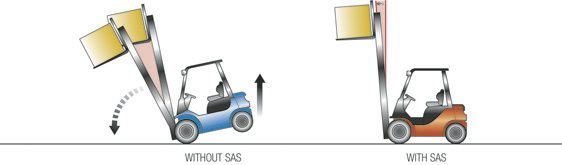

The second feature of SAS is the Active Mast Function Control System. This feature focuses on the longitudinal stability of the forklift and is able to detect the load weight and extended mast height. The system then deploys forward tilt control or rear-tilt control and reduces the tilt speed of the mast by half of its unrestricted speed. With the mast under control, the threat of a front or back tipover is greatly decreased.

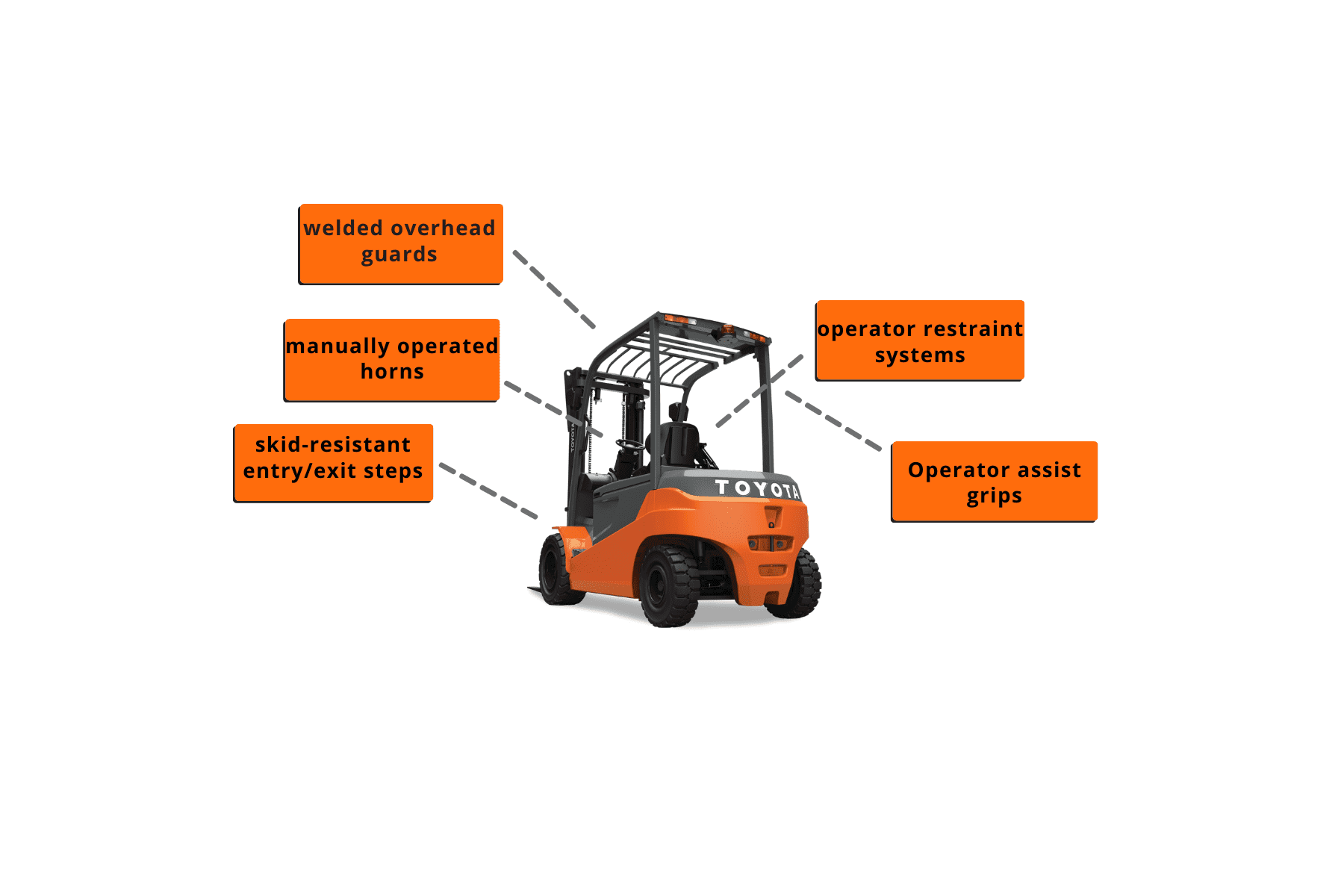

Both of these features work in unison to keep the forklift at optimal stability. While SAS works to prevent lateral and longitudinal tipovers, Toyota also has plenty of other innovative safety features for other hazards in the workplace. Including devices such as welded overhead guards, operator restraint systems, manually operated horns, skid-resistant entry/exit steps, and operator assist grips. These safety devices along with proper training and maintenance will help to prevent a large number of accidents in your business.

SAS is unique to Toyota forklifts and is one of the reasons why Toyota continues to be a leader in material handling safety. The system requires very little maintenance and only needs a 30-second check after every 250 hours of use. At an average maintenance cost of $17 per year, if SAS was able to prevent just one tipover, it would pay for itself more than 1,000 times. SAS is an incredible feature that comes standard on all 4-wheel Toyota forklifts, and it will help keep you and your employees safe

Learn more about our 4-wheel forklifts at: https://sielift.com/new-industrial-equipment/toyota-forklift/ic-cushion-forklifts/mid-ic-cushion-forklifts/

Hello blogger! Informative information There is no doubt that forklift operators play a crucial role in your company, and their work involves some danger. Without the proper safety procedures, your employees may experience major accidents that result in costly repairs and workers’ compensation claims. To operate a business safely and effectively, proper forklift safety is essential. The top safety advice for using forklifts includes examining each forklift daily, while operating forklifts wear the proper attire, understand the forklift classes, making sure the forklift is stable and more. You can also go to our website to learn more.