“Employers have a responsibility to protect their employees from the brutal summer heat, but protection also significantly impacts the bottom line, since productivity notoriously slows down during the summer,” says Terry Wickman, President of Keytroller.” Keeping your forklift operators safe from the summer heat ensures better productivity for tomorrow and years beyond.” Not only does heat directly affect the employees working in it, but it can also affect the equipment they need to get the job done. Here are a few things to keep in mind as the summer temperatures continue to rise and how to prepare your material handling equipment.

Chances are you’ve heard of heat strokes and exhaustion from the sun, we as humans can experience but, do you know how the heat affects your forklifts and material handling equipment? As aforementioned, paying extra attention to your machinery can prevent a less productive workplace. If a piece of equipment isn’t working properly, due to heat, it can hurt the employees and customers and it is not likely that safety will be the first thing on an operator’s mind when maneuvering your facility. While keeping your application as cool as possible for your operators and associates, let’s start with the obvious ways to prevent equipment mishaps.

Chances are you’ve heard of heat strokes and exhaustion from the sun, we as humans can experience but, do you know how the heat affects your forklifts and material handling equipment? As aforementioned, paying extra attention to your machinery can prevent a less productive workplace. If a piece of equipment isn’t working properly, due to heat, it can hurt the employees and customers and it is not likely that safety will be the first thing on an operator’s mind when maneuvering your facility. While keeping your application as cool as possible for your operators and associates, let’s start with the obvious ways to prevent equipment mishaps.

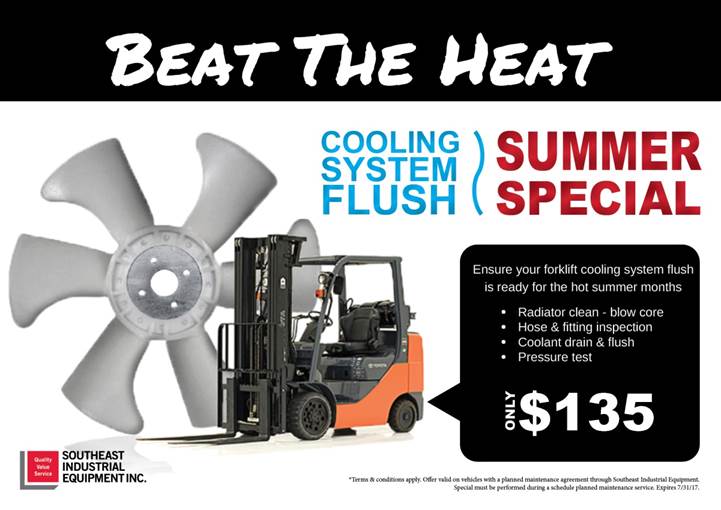

- Overheating: Just as too much heat can cause internal issues with us; it can do the same with forklifts. Therefore, it is important to keep your cooling system, in an internal combustion forklift, in tip-top shape.

- Be sure to keep coolant fluid levels up to, at least, the minimum level. Failure to do so could result in engine damage.

- Regularly replace and replenish coolant liquids. The liquid deteriorates and the chemicals can cause further damage to the coolant system mechanisms.

- Check the radiator for any damage. Cracked or malfunctioning radiators can cause the pressure to drop drastically which causes important coolant flow, overheating, and possible leaking. This depressurization can also cause damage to the transmission.

- Check radiator hoses for cracks and tightness because heat enhances the effect of cracking and deterioration of rubber. If you notice a radiator hose is loose or cracked, replace it ASAP.

- Internal Combustion Forklifts – regularly check filters and oil to ensure that your forklift is ready to operate in the heat.

- Electric Forklifts – High temperatures of the summer cause concern for excess corrosion and low fluid levels. The extreme heat causes evaporation of the battery fluids which can lead to a decrease in the length of your forklift’s life. Avoid this by making sure that you have the correct level of water in the battery cells and that the PH is right for the battery.

- Tires – As mentioned before, heat enhances the effects of cracking and deterioration in rubber.

- Pneumatic tires – It is important to check the pressure in the tires, because when the heat raises so does the pressure in your tire. It’s never a bad idea to let a little bit of air out in the summer.

- You should always check to make sure that your tires are properly inflated, no matter what season it is, especially in the summer. Doing all of these things should help prevent a blowout.

- Maintenance – No one wants to lose time or money, so it is super important to be on top of your maintenance schedule during the summer.

- Performing regular inspections and maintenance is key to preventing the majority of heat-related issues with your forklift and material handling equipment.

No matter the season, it is always important to inspect your forklift before beginning any job. Inspection can save everyone a lot of trouble. Remember to always make sure you’re ready for a safe shift so you can get your job done quickly and enjoy some fun in the sun!

Interesting article and very informational. Forklifts are very useful for managing your day to day warehouse operations, so there maintenance is very important. Thanks for uploading this article. Keep uploading.