Forklift attachments are highly underrated; many people think that attachments are only useful for certain industries handling unique loads, but that is not the case. In fact, forklift attachments can add ease to handling any load.

Utilizing the right attachment can reduce handling time, manpower, fuel consumption, and the chance of damaging the product. There are several types of forklift attachments, so how do you know which is the right one for you? When choosing an attachment for your forklift, here are 6 questions to ask:

- What is the weight of the load?

- What height does the load need to be lifted?

- How do you want to handle the load?

- How many hydraulic functions will be required?

- Will the attachment be required full time or part time?

- Will operators need training in order to operate the attachment? If so, how many operators will need training?

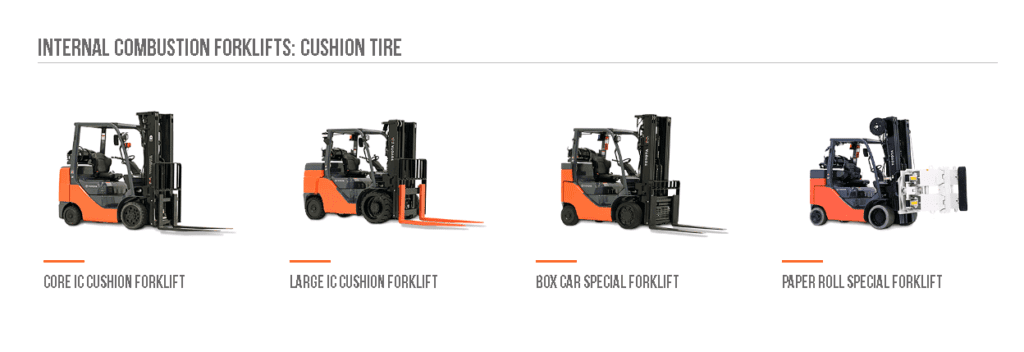

At Southeast Industrial Equipment we have a full staff of educated territory managers and support managers that can assist you with answering these questions, as well as, walk you through the most popular forklift attachments as seen in the infographic below. From paper roll handlers to bale clamps, the possibilities for forklift attachments are virtually endless.

Considering the purchase of an attachment? Contact one of our experienced territory managers to find out if purchasing an attachment makes sense for your application.

No matter what you need, Southeast Industrial Equipment has made it easy for you to get everything from racking to safety products using our online warehouse catalog. Request a

No matter what you need, Southeast Industrial Equipment has made it easy for you to get everything from racking to safety products using our online warehouse catalog. Request a