Agriculture has always been a cornerstone of human civilization, and as technology evolves, so does the efficiency and effectiveness of farming practices. Among the many innovations that have transformed the agricultural landscape, forklifts stand out as a vital tool that has revolutionized how farms operate. While traditionally associated with warehouses and manufacturing, forklifts have become indispensable in the agriculture sector, helping to enhance productivity, reduce labor costs, and ensure the smooth handling of a wide range of farming activities.

The Versatile Role of Forklifts on the Farm

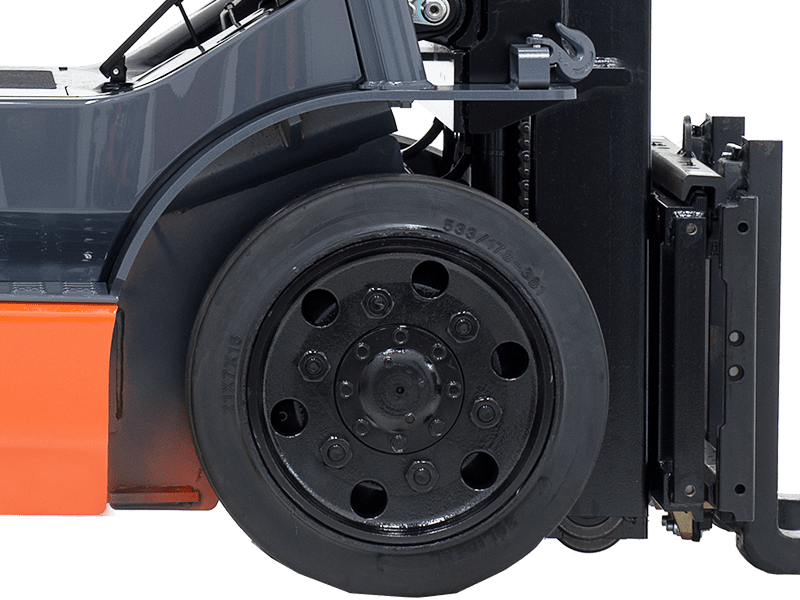

Forklifts in agriculture are versatile machines that perform various tasks, making them a key asset in daily farm operations. From moving pallets of produce to transporting heavy equipment, forklifts streamline many labor-intensive processes. Here’s how forklifts are making a difference on the farm:

1. Efficient Handling of Produce

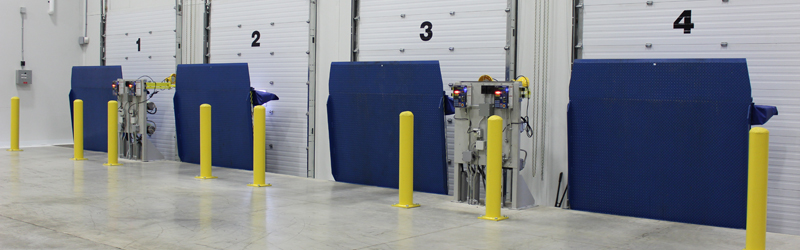

One of the primary uses of forklifts in agriculture is the efficient handling and transportation of produce. During harvest season, forklifts are used to quickly and safely move large quantities of fruits, vegetables, and grains from the fields to storage facilities or transportation vehicles. By using forklifts, farmers can significantly reduce the time and labor required to handle produce, ensuring that it is moved quickly and safely, thus minimizing spoilage and maintaining product quality.

2. Loading and Unloading Equipment

Agriculture often involves the use of heavy machinery and equipment, from tractors to irrigation systems. Forklifts play a crucial role in loading and unloading this equipment, particularly when it needs to be transported to different parts of the farm or between different locations. Their ability to lift and carry heavy loads makes forklifts essential for moving large machinery, saving time and reducing the physical strain on farm workers.

3. Palletizing and Stacking

In modern farming, many products are stored and transported on pallets. Forklifts are used to efficiently stack, organize, and retrieve these pallets, whether they are holding bags of seed, fertilizers, or harvested crops. This not only optimizes storage space but also ensures that products are handled carefully to avoid damage.

4. Supporting Greenhouse Operations

Greenhouses require precise control over environmental conditions and often involve the handling of delicate plants and materials. Forklifts are used in these environments to move pots, trays, and growing materials, as well as to assist in the construction and maintenance of greenhouse structures. Their maneuverability allows them to operate in tight spaces, making them ideal for greenhouse settings.

5. Handling Feed and Fertilizer

Livestock farming and crop production both require the efficient handling of feed and fertilizer. Forklifts are used to move large quantities of these materials, whether in bags, bales, or bulk containers. This not only speeds up the distribution process but also reduces the risk of injury to workers who would otherwise have to manually handle these heavy loads.

6. Supporting Harvesting Operations

During harvest time, forklifts are often used in conjunction with other machinery to support the collection and transportation of crops. For example, forklifts can be used to transport bins or crates of harvested fruits and vegetables from the field to processing areas, reducing the time between harvesting and processing, which is crucial for maintaining freshness.

Advantages of Using Forklifts in Agriculture

The integration of forklifts into agricultural operations offers several advantages:

– Increased Efficiency: Forklifts significantly reduce the time required to move and handle materials, allowing farms to operate more efficiently.

– Labor Savings: By taking on tasks that would otherwise require multiple workers, forklifts reduce the need for manual labor, leading to cost savings and improved worker safety.

– Versatility: Forklifts can be used in a wide range of tasks, from handling delicate plants to transporting heavy machinery, making them a valuable asset for any farm.

– Safety: The use of forklifts reduces the physical strain on workers and minimizes the risk of accidents associated with manual handling of heavy loads.

Forklifts have become an essential part of modern agriculture, providing farms with the tools needed to operate more efficiently and effectively. By streamlining the handling of produce, equipment, and materials, forklifts help to reduce labor costs, improve safety, and enhance productivity on the farm. As the agricultural industry continues to evolve, the role of forklifts will undoubtedly continue to grow, driving further advancements in farming practices and helping to meet the ever-increasing demand for food and agricultural products.