Forklifts are vital tools across various industries, and selecting the right type of tires is crucial for their optimal performance. Among the different types of forklift tires, cushion tires stand out for their specific applications and advantages. In this blog, we’ll delve into what cushion forklift tires are, their benefits, and the best applications for these tires.

What Are Cushion Forklift Tires?

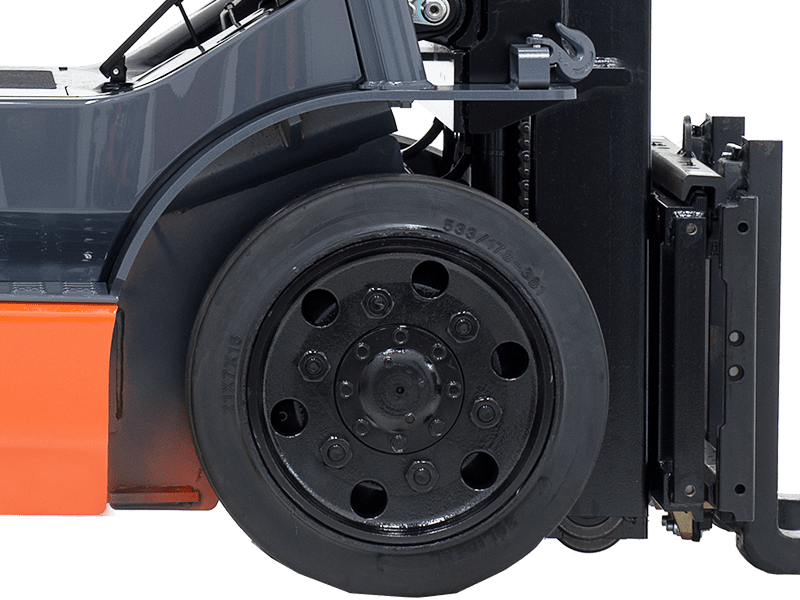

Cushion tires are made from solid rubber and are typically fitted onto a metal band. Unlike pneumatic tires, which are filled with air, cushion tires are solid and therefore resistant to punctures and flats. These tires are designed for indoor use and smooth surfaces, making them ideal for warehouses and other indoor facilities.

Benefits of Cushion Forklift Tires

1. Compact and Maneuverable

One of the primary advantages of cushion tires is their compact size. Because they are smaller than pneumatic tires, forklifts equipped with cushion tires have a smaller turning radius. This makes them highly maneuverable, especially in tight spaces such as narrow warehouse aisles.

2. Durability and Longevity

Cushion tires are made of solid rubber, which makes them incredibly durable. They are resistant to punctures, cuts, and other forms of damage that can occur in industrial environments. This durability translates to a longer lifespan compared to pneumatic tires, reducing the need for frequent replacements and minimizing downtime.

3. Cost-Effective

Due to their long lifespan and resistance to damage, cushion tires can be more cost-effective over time. They require less frequent replacement and maintenance, which can result in significant savings for businesses. Additionally, their initial cost is generally lower than that of pneumatic tires.

4. Smooth and Stable Ride

Cushion tires provide a smooth and stable ride on flat, hard surfaces. Their solid construction helps to absorb shocks and vibrations, enhancing operator comfort and reducing fatigue. This stability is essential for maintaining safety and efficiency in indoor operations.

5. Lower Rolling Resistance

Cushion tires have lower rolling resistance compared to pneumatic tires, meaning they require less energy to move the forklift. This can lead to improved fuel efficiency and reduced operating costs, particularly in electric forklifts where battery life is a critical factor.

Best Applications for Cushion Forklift Tires

Cushion tires are best suited for indoor applications and smooth, even surfaces. Here are some of the environments where cushion tires excel:

1. Warehouses and Distribution Centers

Cushion tires are ideal for warehouses and distribution centers with smooth concrete floors. Their compact size and maneuverability make them perfect for navigating narrow aisles and tight spaces commonly found in these settings.

2. Manufacturing Facilities

In manufacturing facilities, forklifts often need to operate in confined areas with smooth floors. Cushion tires provide the necessary stability and durability to handle the demands of manufacturing environments.

3. Loading Docks

Loading docks with smooth, flat surfaces are another suitable environment for cushion tires. The tires’ durability helps withstand the constant loading and unloading processes, ensuring reliable performance.

4. Indoor Retail Operations

Retail environments with polished floors benefit from the smooth ride and maneuverability of cushion tires. Forklifts can efficiently transport goods without causing damage to the flooring.

When Not to Use Cushion Tires

While cushion tires offer numerous benefits, they are not suitable for all applications. Here are some scenarios where cushion tires may not be the best choice:

– Outdoor Use: Cushion tires are not designed for rough or uneven terrain. For outdoor use, especially on gravel, dirt, or other rough surfaces, pneumatic tires are a better option.

– Wet or Slippery Surfaces: Cushion tires may not provide adequate traction on wet or slippery surfaces, potentially leading to safety hazards.

– Heavy Load Handling: If your operation involves handling very heavy loads on a regular basis, pneumatic tires may offer better support and stability.

Cushion forklift tires are a versatile and cost-effective option for indoor applications with smooth, flat surfaces. Their durability, maneuverability, and smooth ride make them a popular choice for warehouses, manufacturing facilities, and other indoor environments. By understanding the benefits and limitations of cushion tires, you can make informed decisions to optimize your forklift operations and ensure safety and efficiency in your workplace.

Investing in the right type of forklift tires for your specific needs can lead to significant improvements in productivity and cost savings, making cushion tires an excellent choice for many indoor material handling applications.