Your company needs a new forklift, but where do you begin? Whether you’re a seasoned vet or a beginner, choosing a new piece of equipment can be stressful.

The pressure is on to find the perfect forklift that will increase productivity without breaking the bank. There are several factors that go into choosing the right piece of equipment; here’s what you need to know to make your mission a success.

Indoors vs. Outdoors

The environment you operate in answers the first major question, Electric or Internal Combustion (IC).

If you will be operating inside, electric is the way to go. Electric forklifts offer decreased fumes and noise, making them ideal for an indoor warehouse environment.

While Electric forklifts might cost more initially, they tend to have a lower operating cost per year than Internal Combustion (IC) Lifts. Electric forklifts don’t require fuel or oil changes but they aren’t totally maintenance free, requiring upkeep for batteries. If the water level inside the battery gets too low it can dry out, requiring a replacement or repair. You must also factor in the cost of a charging station and consider purchasing a backup battery.

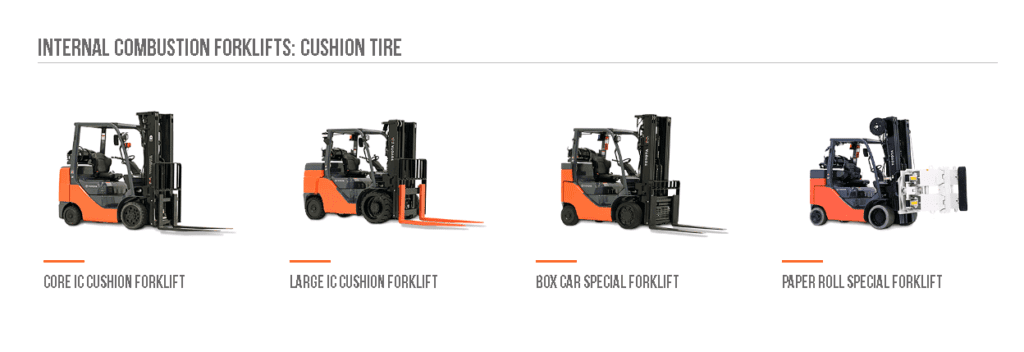

If you need a forklift that can handle rough terrain and the wear and tear of being outdoors, then you’ll want an Internal Combustion Lift. Designed to handle larger loads than their electric counterparts, IC lifts can run on Diesel, Liquid Petroleum Gas (LPG), or Gasoline. Diesel engines are designed for uneven surfaces and heavy loads and work well with attachments. LPG lift trucks are great if you need a versatile piece of equipment that can operate indoors and outdoors.

Selecting a model

Now that you’ve decided between Electric and IC, it’s time to get specific. Knowing your lifting capacity and height needs will guide you to the right model. Many buyers find it useful to purchase a lift that slightly exceeds their current requirements.

Overall Cost of Equipment

Once you’ve found the perfect model, it’s easy to get caught up in the initial cost and lowest price tag, but doing so can cost you more. When in the market for new equipment it’s important to think long-term and consider the lifetime cost of your forklift. Used equipment can be a bargain, but new equipment offers warranties and peace of mind that some used equipment may not afford.

Knowing what the dealer has to offer helps you tremendously. Ask about services and maintenance plans that support your new investment. Find out if your dealer provides OEM parts you may need, and ask about any warranty the lift may come with.

Most importantly, do your research before hitting the market. Take your time and don’t just jump at the cheapest option.

What a great post! Choosing the correct one in beyond crucial for a good and comfortable work.

I’ll keep reading you!