Category: Equipment Inspections

Southeast Industrial Equipment offers safety training opportunities and equipment specialists to perform annual and semi-annual equipment inspections to keep your lifts in compliance with OSHA standards. Whether you need your annual aerial work platform inspections completed or training to keep your employees up-to-date on the latest lift truck rules and regulations, we offer the options for your business.

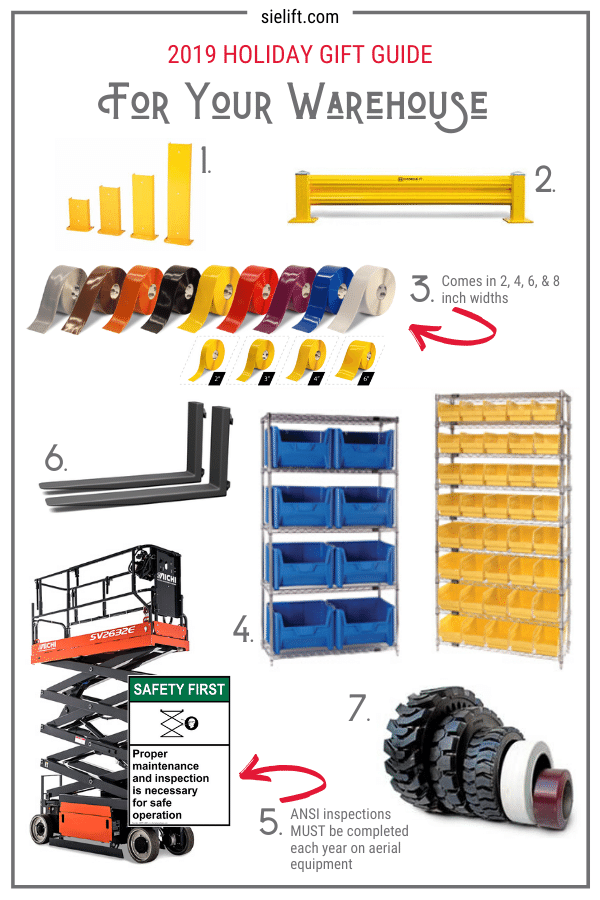

Aerial Work Platform Inspections

Aerial work platform inspections must be done 13 months after the previous inspection annually.

The American National Standards Institute (ANSI) has standards for owning and operating aerial work platforms.

ANSI/SIA A92.6 & A92.5 section 6.7; “The owner of an aerial platform shall ensure that an annual inspection is performed on the aerial platform no later than thirteen (13) months from the date of the prior annual inspection. The inspection shall be made by a person(s) qualified as a mechanic on the specific type of aerial platform or one having similar design characteristics. The inspection shall be in accordance with items specified by the manufacturer for an annual inspection. The owner shall not place the aerial platform into service until all malfunctions and problems have been corrected.”

What is to be inspected annually, you might ask? See the limited list below and note that inspections of all equipment should be performed and documented daily.

Operational inspections include/not limited to:

- Lift, drive and emergency controls

- Horn

- Parking brake

- Battery charger

- Limit switches

- Other safety devices

- And more!

Visual Inspections include/not limited to:

- Damaged, worn or missing parts

- Leaks

- Tires

- Railings

- Entry gates or chains

- Loose pins or hardware

- Structural damage

- And more!

Southeast Industrial Equipment offers Aerial Work Platform inspections service according to ANSI guidelines utilizing our certified equipment specialists to help you avoid costly fines due to non-compliance. Upon completion of necessary repairs or preventative maintenance, SIE will issue certification. We have 10 locations throughout the southeast with full working shops, over 150+ certified technicians and a fleet of service vans ready to come to your facility. Keeping the headache of annual inspections as convenient as possible.

To learn more about ANSI Certified Annual Inspections for your aerial lift visit www.ansi.org and read the OSHA Aerial Lift Fact Sheet >