Dock levelers are essential components in modern warehouse and distribution centers, facilitating the smooth transfer of goods between trucks and the dock. Their role in ensuring safety, efficiency, and operational effectiveness cannot be overstated. In this blog, we will delve into the importance of this equipment, the different types available, and how to choose the right one for your facility.

What Are Dock Levelers?

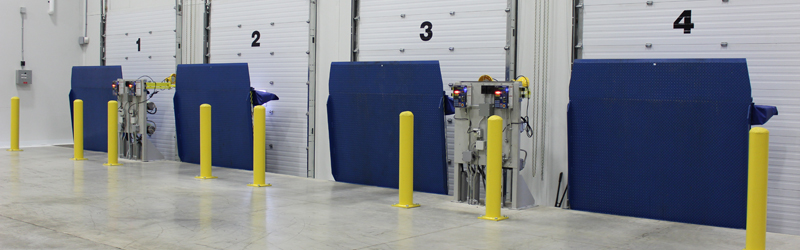

Dock levelers are adjustable platforms installed at loading docks. They bridge the gap between a dock and a truck, allowing for the safe and efficient loading and unloading of goods. They accommodate the height differences between various trucks and the dock, providing a smooth transition for forklifts and other material handling equipment.

The Importance of Dock Levelers

1. Safety

– A dock leveler play a critical role in maintaining safety during loading and unloading operations. They help prevent accidents caused by uneven surfaces, reducing the risk of injuries to workers and damage to goods and equipment.

2. Efficiency

– By providing a smooth and level surface, this equipment enables faster and more efficient movement of goods. This efficiency is crucial for maintaining the flow of operations, especially in high-volume facilities.

3. Flexibility

– Different trucks come with varying bed heights. A Dock leveler accommodates these variations, making it easier to handle diverse types of vehicles without requiring multiple dock heights.

Types of Dock Levelers

1. Mechanical Dock Levelers

– These are manually operated and use a system of springs and levers to adjust the platform. They are cost-effective and suitable for facilities with lower volumes of traffic.

2. Hydraulic Dock Levelers

– Hydraulic levelers use a system of hydraulics for operation, providing smoother and easier adjustments. They are ideal for high-traffic facilities and offer enhanced safety features.

3. Air-Powered Dock Levelers

– These levelers use an airbag or bellows system to raise and lower the platform. They are known for their low maintenance requirements and are suitable for environments where cleanliness is essential.

4. Vertical Dock Levelers

– Vertical levelers store in an upright position when not in use, making them ideal for facilities that prioritize security and cleanliness. They allow for complete control of the dock door.

Choosing the Right Dock Leveler

Selecting the appropriate dock leveler for your facility involves considering several factors:

1. Load Capacity

– Determine the maximum load capacity required based on the heaviest equipment and goods handled in your facility.

2. Frequency of Use

– Assess how often the leveler will be used. High-frequency operations may benefit from hydraulic or air-powered levelers due to their ease of use and durability.

3. Type of Vehicles

– Consider the variety of trucks and trailers that will use the dock. Ensure the leveler can accommodate the height variations and types of vehicles.

4. Environmental Conditions

– Take into account the working environment. For example, cold storage facilities might require specialized dock levelers that can withstand extreme temperatures.

5. Budget

– Evaluate your budget, balancing the initial cost with long-term benefits such as maintenance, durability, and efficiency.

Dock levelers are indispensable for the smooth and safe operation of any warehouse or distribution center. By understanding the different types of dock levelers, their benefits, and how to choose the right one, businesses can enhance their operational efficiency and safety. Regular maintenance and proper training further ensure that your equipment continues to perform optimally, providing long-term benefits and reliability. Investing in the right dock leveler, like our great models from Blue Giant, can make a significant difference in the overall productivity and safety of your facility.