When it comes to the world of material handling and industrial equipment, forklifts are the

workhorses that keep operations moving smoothly. Behind the scenes of these powerful machines lies a wealth of information crucial for their safe and efficient use – the forklift data plate. Let’s delve into the significance of these seemingly unassuming metal plates and understand why they are a vital aspect of forklift operation.

What is a Forklift Data Plate?

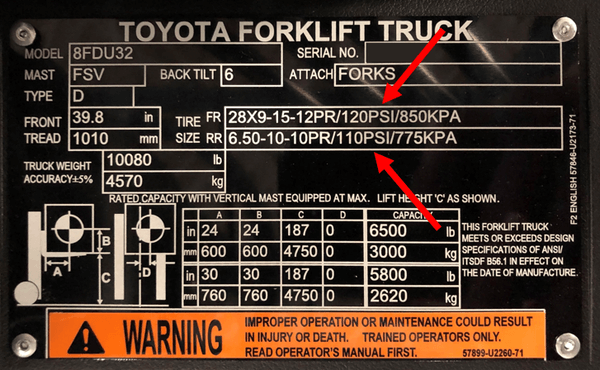

A forklift data plate is a small, usually metal, identification tag affixed to the forklift. This plate contains a wealth of information about the forklift’s specifications, capacities, and other essential details necessary for its safe and proper operation. Think of it as a forklift’s ID card, providing key insights into its capabilities and limitations.

Understanding the Information

1. Manufacturer Information: The data plate typically starts with details about the forklift’s manufacturer. This includes the company name, logo, and sometimes a serial number unique to that particular forklift.

2. Capacity Specifications: One of the most critical pieces of information on the data plate is the forklift’s lifting capacity. This specifies the maximum weight the forklift is designed to lift safely. Exceeding this limit can lead to instability and potential accidents.

3. Load Center: The load center is another crucial factor, indicating the distance from the forks to the center of gravity of the load. It helps operators understand how different loads will affect the forklift’s stability.

4. Mast and Fork Details: Information about the forklift’s mast, including its height and type, is often specified on the data plate. Fork dimensions, such as length and width, are also provided, ensuring compatibility with various loads.

5. Tire Information: Different forklifts come with various tire types, each suitable for specific applications. The data plate specifies the recommended tire type, ensuring optimal performance and safety.

6. Engine Details: For internal combustion forklifts, the data plate provides information about the engine, including its type, displacement, and power output. This data is crucial for maintenance and troubleshooting.

7. Fuel Type: The type of fuel the forklift uses – whether electric, propane, diesel, or other – is clearly indicated on the data plate. This information is vital for proper handling, refueling, and maintenance.

Ensuring Safety and Compliance

The primary purpose of the forklift data plate is to promote safety and compliance. By providing accurate and comprehensive information, the data plate empowers operators and supervisors to make informed decisions, preventing accidents and equipment misuse. It also serves as a quick reference guide for maintenance personnel, ensuring that the forklift is serviced according to the manufacturer’s specifications.

In the fast-paced world of material handling, forklifts are indispensable tools, and their safe operation is paramount. The unassuming forklift data plate serves as a silent guardian, offering a wealth of information crucial for ensuring the forklift’s efficiency, safety, and compliance. As operators and businesses navigate the intricate landscape of material handling, understanding and respecting the information on the forklift data plate is a fundamental step toward a smoother, safer, and more productive operation.