Unlock the full potential of your warehouse with Southeast Industrial Equipment Inc., your one-stop shop for industry-specific racking solutions! Maximize storage capacity, streamline operations, and boost efficiency – all with the right racking system tailored to your unique needs.

SIE Has the Racking Systems You Need

Different lines of business, be it manufacturing or warehousing, call for various types of racking. SIE knows it’s important to set up a racking system that aligns with your industry to promote maximum efficiency and productivity. Take a look at what racking systems SIE suggests for your industry:

General Warehousing:

Selective Pallet Racks: The workhorse of warehouses, selective pallet racks offer unparalleled versatility and easy access to palletized goods. They’re perfect for storing a wide range of items and ideal for warehouses with moderate to high product turnover.

Drive-In & Push-Back Racks: When maximizing space utilization is your top priority, consider high-density storage solutions like drive-in and push-back racks. These systems create a compact storage block, ideal for storing large quantities of similar items.

Freezer/Cooler Warehousing:

Industrial-Grade Selective Pallet Racks: Maintain optimal product temperature and organization with our industrial-grade selective pallet racks. Engineered to withstand cold environments, these racks ensure the integrity of your temperature-sensitive goods.

High-Bay Pallet Racks: Take advantage of your warehouse’s vertical space with high-bay pallet racks. These robust systems allow you to maximize storage capacity without sacrificing accessibility

Retail Warehousing:

Shelving & Cantilever Rack Systems: Cater to your fast-paced retail environment with our innovative shelving and cantilever rack systems. Shelving units provide easy access to high-demand items, while cantilever racks offer versatile storage for bulky or oddly shaped merchandise.

Mezzanine Systems: Double your usable floor space with mezzanine systems. Create designated picking areas or office space above your existing footprint, enhancing order fulfillment efficiency and overall productivity.

General Manufacturing:

Heavy-Duty Pallet Racks: Form the backbone of your production line with our heavy-duty pallet racks. Store raw materials, finished goods, and heavy machinery securely and efficiently.

Cart Racking Systems: Optimize tool and die storage with versatile cart racking systems. These systems keep your essential tools organized and readily accessible, minimizing downtime and maximizing production efficiency.

SIE has the inventory to maximize your warehouse footprint, your workflow output, and job completion. Check out our entire warehouse catalog to find the equipment that will upgrade your facility’s production!

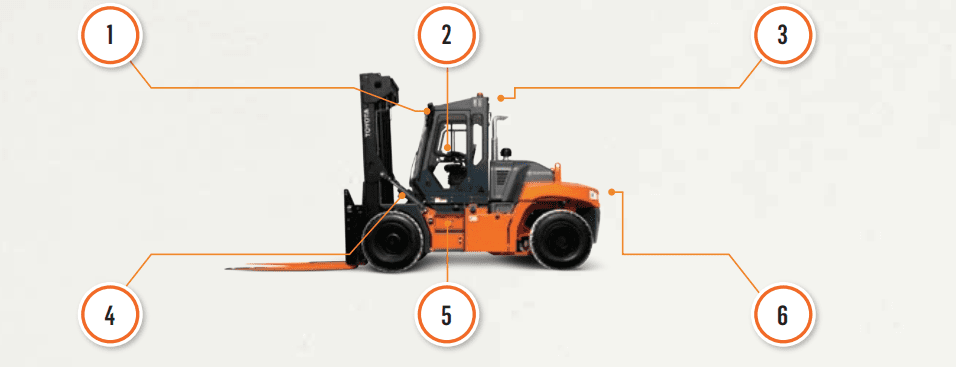

Want a visual? Check out the Toyota Forklift Warehouse Racking Solutions Infographic to understand different racking systems and their applications.

Contact SIE Today to Maximize Your Warehouse Productivity

Still have questions or a unique storage challenge? Southeast Industrial Equipment Inc. is here to help! Our racking specialists will conduct a comprehensive needs assessment to design a customized storage solution that perfectly aligns with your specific business requirements.

Contact us for a free quote and unlock the potential of your warehouse!

to deliver gifts to everyone on the nice list! Why not buy a gift for your forklift operator / operators with these great ideas including our favorite : this “Star Wars” inspired t-shirt.

to deliver gifts to everyone on the nice list! Why not buy a gift for your forklift operator / operators with these great ideas including our favorite : this “Star Wars” inspired t-shirt.

Bendi – The leader in articulated forklifts

Bendi – The leader in articulated forklifts Drexel – The very narrow aisle and narrow aisle long load side loading solution.

Drexel – The very narrow aisle and narrow aisle long load side loading solution.